Technical Data Sheet JM-FF001-XXXX( V2.2)

Product Information High Effective Absorb Formaldehyde FF series

Product Information High Effective Absorb Formaldehyde FF series

General Description :

Nano Coat treatment for rapid decomposition & removal of formaldehyde pollutants to provide a safer living and working environment.

Features :

►Excellent Decomposition of Formaldehyde pollutants

►Automotive Interior, Train Carriages and Aircraft Cabins

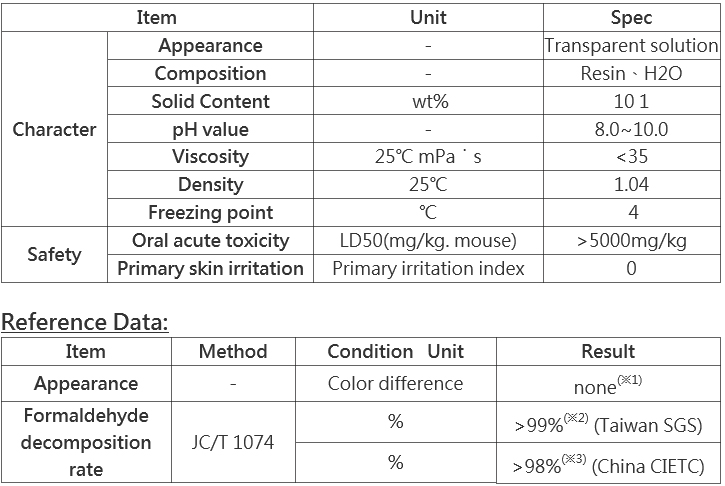

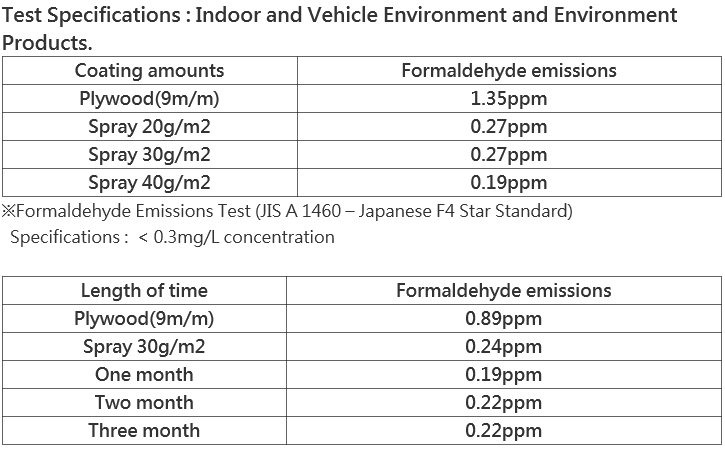

Typical Physical Properties

►These properties are typical but should not be considered specifications.

Nano Coat treatment for rapid decomposition & removal of formaldehyde pollutants to provide a safer living and working environment.

Features :

►Excellent Decomposition of Formaldehyde pollutants

- ►Colorless & Transparent

- ►Environmental friendly

- ►Wood and Flooring products, Furniture and Varnished products

►Automotive Interior, Train Carriages and Aircraft Cabins

Typical Physical Properties

►These properties are typical but should not be considered specifications.

※1.Methodology : Spray 20g/m2 on the substrate (wood、plastic).

※2. Methodology : per JC/T 1074

Spray 30g/m2 on both sides of glass specimen (30c30cm).

Place 3 pcs into a 1m3 container, pour formaldehyde gad (10ppm), subject to fan-speed of 0.9~1.1m/s.

Take sample readings after 1 hour.

※3. Tested by National Center for Quality Supervision (CIETC).

※2. Methodology : per JC/T 1074

Spray 30g/m2 on both sides of glass specimen (30c30cm).

Place 3 pcs into a 1m3 container, pour formaldehyde gad (10ppm), subject to fan-speed of 0.9~1.1m/s.

Take sample readings after 1 hour.

※3. Tested by National Center for Quality Supervision (CIETC).

Recommended Application Process :

1. Equipment :

(a) Spraying: Spray gun, nozzle diameter 0.3mm~1mm, air pressure 0.3kg~3kg under room

temperature 10~40℃

(b) Brush coating

2. Process :

(a )Ensure a thorough cleaning of the substrate surface.

(b)Apply Nano Coat after cleaned surface is dry.

Spraying(ensure minimum of 30cm distance from the nozzle to the surface) or Brush coating.

(c)Rinse equipment with water after application.

※ The data above is for reference only.

Rubberized surfaces may require plasma treatment.

Please use the materials based on actual substrate & environment.

3. Standard Packing:

20kg/plastic drum.

4. Storage:

Please store under room temperature 25℃, humidity>45% with good ventilation and avoid exposure to direct sunshine.

Keep container sealed after opening.

Shelf-life : 6 months from date of manufacture.

► Safety & Notice

1. In order to ensure product reliability, please apply under clean environment.

2. The surface of thin film does not resist water & wiping.

3. Keep containers sealed after opening and store under recommended environment.

4. Minimum Storage temperature = 5℃.

5. Ensure good ventilation.

6. Consult a physician should any allergies occur.

7. Please refer to Material Safety Data Sheet for more details.

Product Stewardship

JM encourages its customers to ensure that JM products are not used in ways for which they are not intended or tested.

Our personnel are available to answer your questions and to provide reasonable technical support.

JM safety data sheets should be consulted prior to use.

Disclaimer

No freedom from infringement of any patents owned by JM or others is to be inferred.

The Customer is responsible for determining whether products and the information in this document are appropriate for the Customer’s use.

The claims made may not have been approved for use in some countries and JM assumes no obligation or liability for the information in this document.

NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSEDLY EXCLUDED.

1. Equipment :

(a) Spraying: Spray gun, nozzle diameter 0.3mm~1mm, air pressure 0.3kg~3kg under room

temperature 10~40℃

(b) Brush coating

2. Process :

(a )Ensure a thorough cleaning of the substrate surface.

(b)Apply Nano Coat after cleaned surface is dry.

Spraying(ensure minimum of 30cm distance from the nozzle to the surface) or Brush coating.

(c)Rinse equipment with water after application.

※ The data above is for reference only.

Rubberized surfaces may require plasma treatment.

Please use the materials based on actual substrate & environment.

3. Standard Packing:

20kg/plastic drum.

4. Storage:

Please store under room temperature 25℃, humidity>45% with good ventilation and avoid exposure to direct sunshine.

Keep container sealed after opening.

Shelf-life : 6 months from date of manufacture.

► Safety & Notice

1. In order to ensure product reliability, please apply under clean environment.

2. The surface of thin film does not resist water & wiping.

3. Keep containers sealed after opening and store under recommended environment.

4. Minimum Storage temperature = 5℃.

5. Ensure good ventilation.

6. Consult a physician should any allergies occur.

7. Please refer to Material Safety Data Sheet for more details.

Product Stewardship

JM encourages its customers to ensure that JM products are not used in ways for which they are not intended or tested.

Our personnel are available to answer your questions and to provide reasonable technical support.

JM safety data sheets should be consulted prior to use.

Disclaimer

No freedom from infringement of any patents owned by JM or others is to be inferred.

The Customer is responsible for determining whether products and the information in this document are appropriate for the Customer’s use.

The claims made may not have been approved for use in some countries and JM assumes no obligation or liability for the information in this document.

NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSEDLY EXCLUDED.