Product Information JM-PCSP1-TSA1 ( V1.0)

Product Information Nano Photocatalyst Material PCSP1 series

Character & Application:

JM-PCSP1-TSA1 is a nano composite nontoxic surface treatment material for various kinds of plastic materials. It is a environmental friendly aqueous resin for self-cleaning, anti-dust, anti-bacterial, anti-virus…etc.

Function:

Excellent photo catalyst with self-cleaning, anti-dirt function & Anti-bacterial, anti-virus &Anti-dust.

Application:

Plastic products for medical application & Plastic products for building materials.

JM-PCSP1-TSA1 is a nano composite nontoxic surface treatment material for various kinds of plastic materials. It is a environmental friendly aqueous resin for self-cleaning, anti-dust, anti-bacterial, anti-virus…etc.

Function:

Excellent photo catalyst with self-cleaning, anti-dirt function & Anti-bacterial, anti-virus &Anti-dust.

Application:

Plastic products for medical application & Plastic products for building materials.

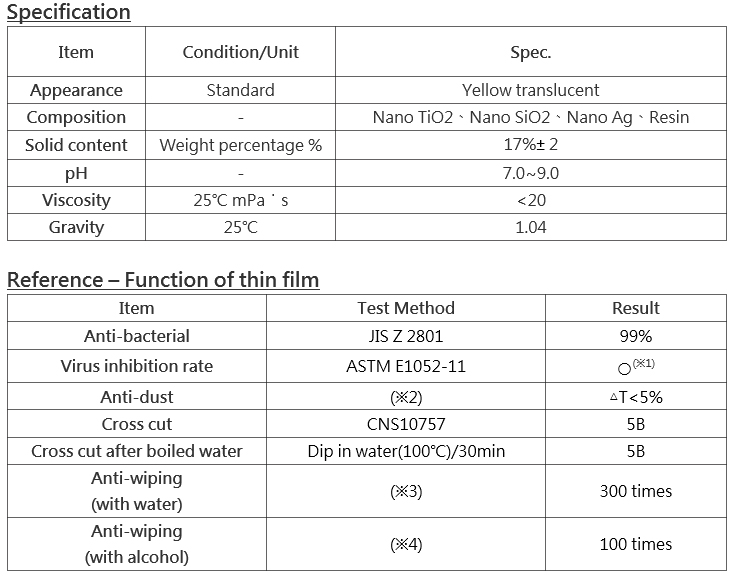

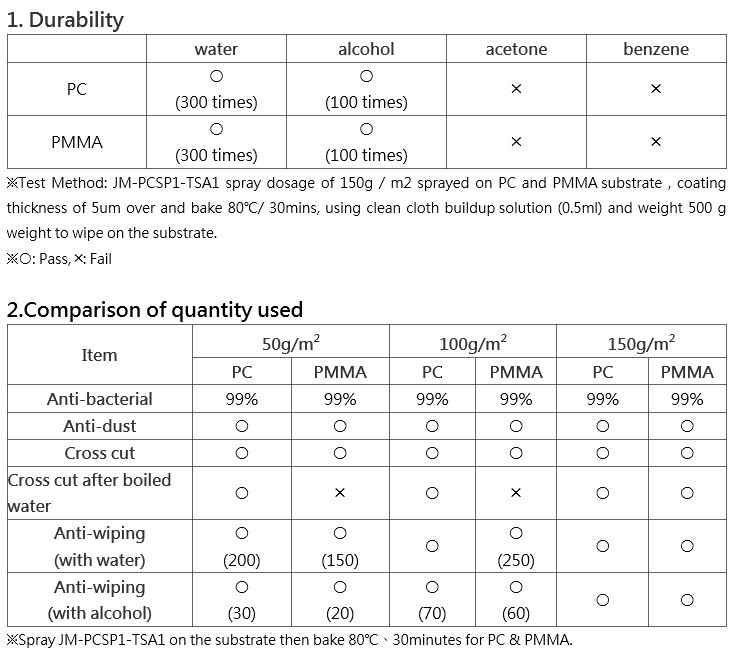

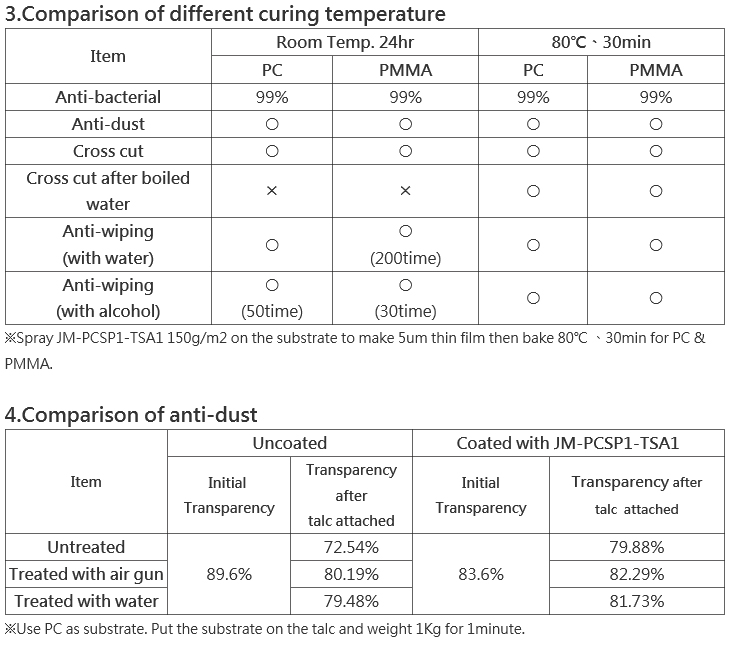

※Test Method: Spray 150g/m2 on the substrate to make a 5um thin film , then bake 80℃ 、30min for PC & PMMA.

※1.Virus inhibition rate: influenza virus and enterovirus .

※2.Test Method:

1: Put the sample on the talc and add a weight of 1Kg for 1 minutes.

2: Check the transparency of the substrate (PC, PMMA) and calculate the average value of 5 spots Transparency of

substrates without coating JM-PCSP1-TSA1 declined more than 10%.

△T is the average change rate of transparency.

※3. Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with water.

No wrinkle, scratch, peeling allowed on the surface.

※4. Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with alcohol.

No wrinkle, scratch, peeling allowed on the surface.

※1.Virus inhibition rate: influenza virus and enterovirus .

※2.Test Method:

1: Put the sample on the talc and add a weight of 1Kg for 1 minutes.

2: Check the transparency of the substrate (PC, PMMA) and calculate the average value of 5 spots Transparency of

substrates without coating JM-PCSP1-TSA1 declined more than 10%.

△T is the average change rate of transparency.

※3. Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with water.

No wrinkle, scratch, peeling allowed on the surface.

※4. Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with alcohol.

No wrinkle, scratch, peeling allowed on the surface.

Process Condition

1. Method :

Spray with a spray gun, diameter 0.3mm~1mm, air pressure 0.3kg~1kg under room temperature 10~40℃ .

2. Process

A. Clean the surface of the substrate.

B. Spraying

C. Curing: room temperature 24 hours or baking 80℃ 30 minutes.

(curing time of room temperature depends on ventilation condition, thickness of the thin film,humidity , types of substrates….etc)

※The data above is for reference. Please use the materials based on actual substrate & environment.

Packing

3kg/plastic can & 20kg/plastic drum.

Recommend Substrate

PC、PMMA.

Storage

Please store between 15~25℃ with good ventilation and avoid the sunshine. Valid 6 month.

Keep well-sealed after open.

Safety and Notice

1. In order to ensure the reliability, please process under clean environment.

2. Keep well sealed after open and store under recommended environment.

3. Keep good ventilation.

1. Method :

Spray with a spray gun, diameter 0.3mm~1mm, air pressure 0.3kg~1kg under room temperature 10~40℃ .

2. Process

A. Clean the surface of the substrate.

B. Spraying

C. Curing: room temperature 24 hours or baking 80℃ 30 minutes.

(curing time of room temperature depends on ventilation condition, thickness of the thin film,humidity , types of substrates….etc)

※The data above is for reference. Please use the materials based on actual substrate & environment.

Packing

3kg/plastic can & 20kg/plastic drum.

Recommend Substrate

PC、PMMA.

Storage

Please store between 15~25℃ with good ventilation and avoid the sunshine. Valid 6 month.

Keep well-sealed after open.

Safety and Notice

1. In order to ensure the reliability, please process under clean environment.

2. Keep well sealed after open and store under recommended environment.

3. Keep good ventilation.