Advanced Nano Composite Material Application

|

Product Information JM-PMWP1-TXA1(V1.0)

Product Information Nano Photocatalyst Material PMWP series

Character & Application:JM-PMWP1-TXA1 is a non-toxic nano composite surface treatment material for various kinds of medical equipment, metal, plastic and construction materials. It is aqueous resin with multi-functions like self-cleaning, anti-corrosion, anti-virus….etc.

Functions:

Plastic building materials & Plastic electronic products.

Functions:

- ►Excellent photo catalyst, anti-dirt, easy to clean.

- ►Anti-corrosion & anti-wiping.

- ►Anti-bacteria, anti-virus.

Plastic building materials & Plastic electronic products.

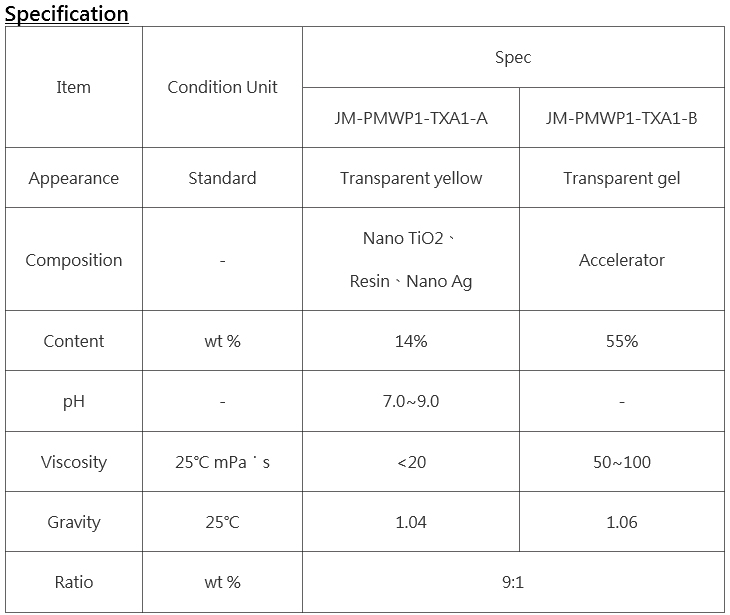

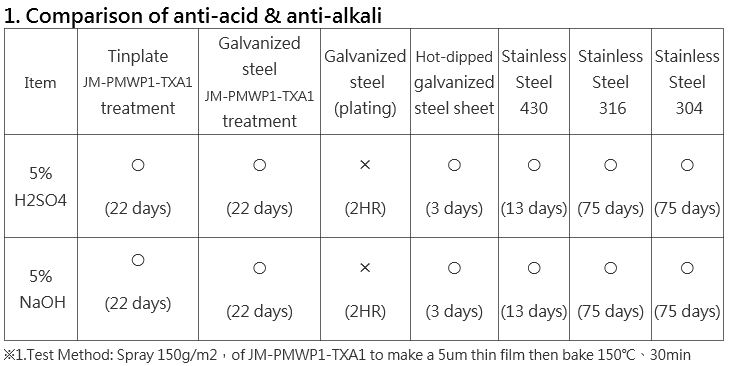

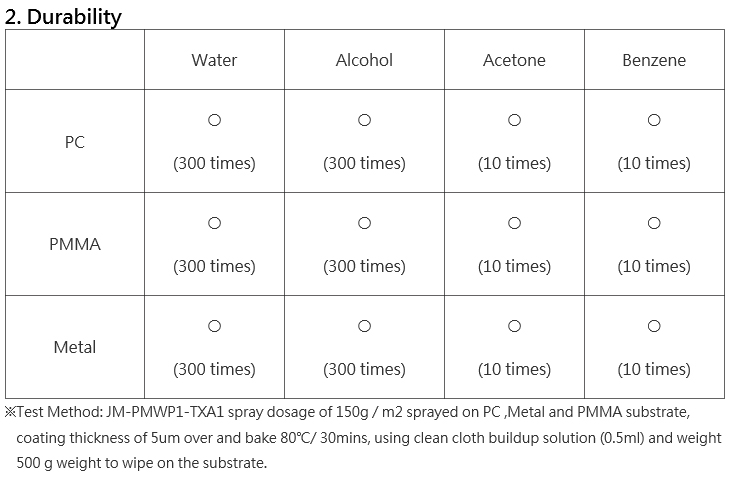

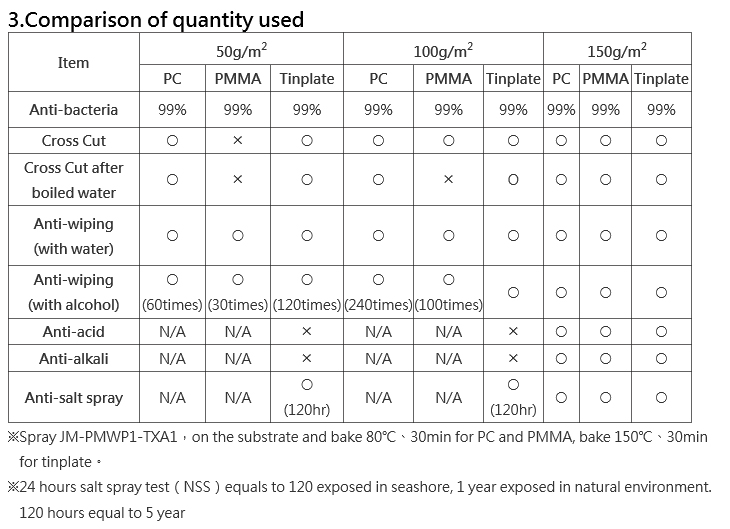

※Test Method: Spray 150g/m2 on the substrate to make a 5um thin film, then bake 80℃、30min for plastic (PC, PMMA),Bake 150℃、30min for metal (tinplate)

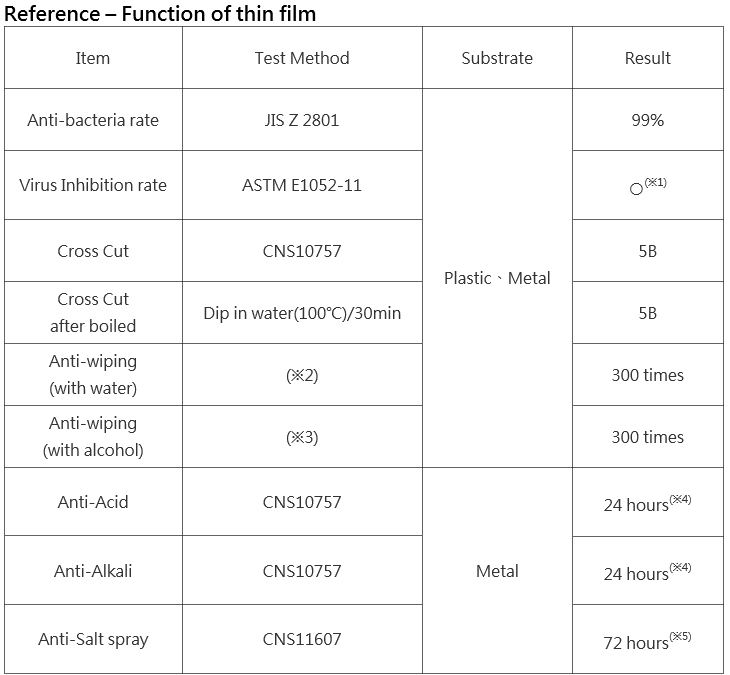

※1 Virus inhibition rate: influenza virus and enterovirus

※2.Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with water. No wrinkle, scratch, peeling allowed on the surface.

※3.Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with alcohol. No wrinkle, scratch, peeling allowed on the surface.

※4.5% H2SO4(acid、pH=0.6 ) or 5% NaOH(alkali、pH=13.6 )dipping 24 hours. No wrinkle, peeling allowed on the thin film.

※5.Test environment 50±5g/L NaCl solution,spray:1.0~2.0 ml/ 80cm2 / hour.

※1 Virus inhibition rate: influenza virus and enterovirus

※2.Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with water. No wrinkle, scratch, peeling allowed on the surface.

※3.Test Method: Load 500g weight on the substrate and wipe by non-dust cloth with alcohol. No wrinkle, scratch, peeling allowed on the surface.

※4.5% H2SO4(acid、pH=0.6 ) or 5% NaOH(alkali、pH=13.6 )dipping 24 hours. No wrinkle, peeling allowed on the thin film.

※5.Test environment 50±5g/L NaCl solution,spray:1.0~2.0 ml/ 80cm2 / hour.

Process Condition

1. Method :Spraying: with a spray gun, diameter 0.3mm~2mm, air pressure 0.3kg~1kg under room temperature 10~40℃

2. Process

1. Method :Spraying: with a spray gun, diameter 0.3mm~2mm, air pressure 0.3kg~1kg under room temperature 10~40℃

2. Process

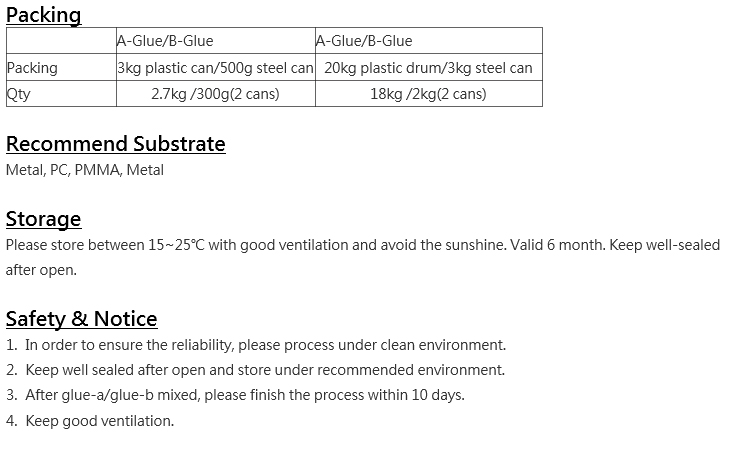

- Clean the surface of the substrate.

- Mixing

Mix JM-PMWP1-TXA1-A & JM-PMWP1-TXA1-B well before using - Spraying

- Ripening : Bake 80℃ 30 minutes or 150℃ 30minutes(depends on the substrate)

- Wash the tools with water after process finished.